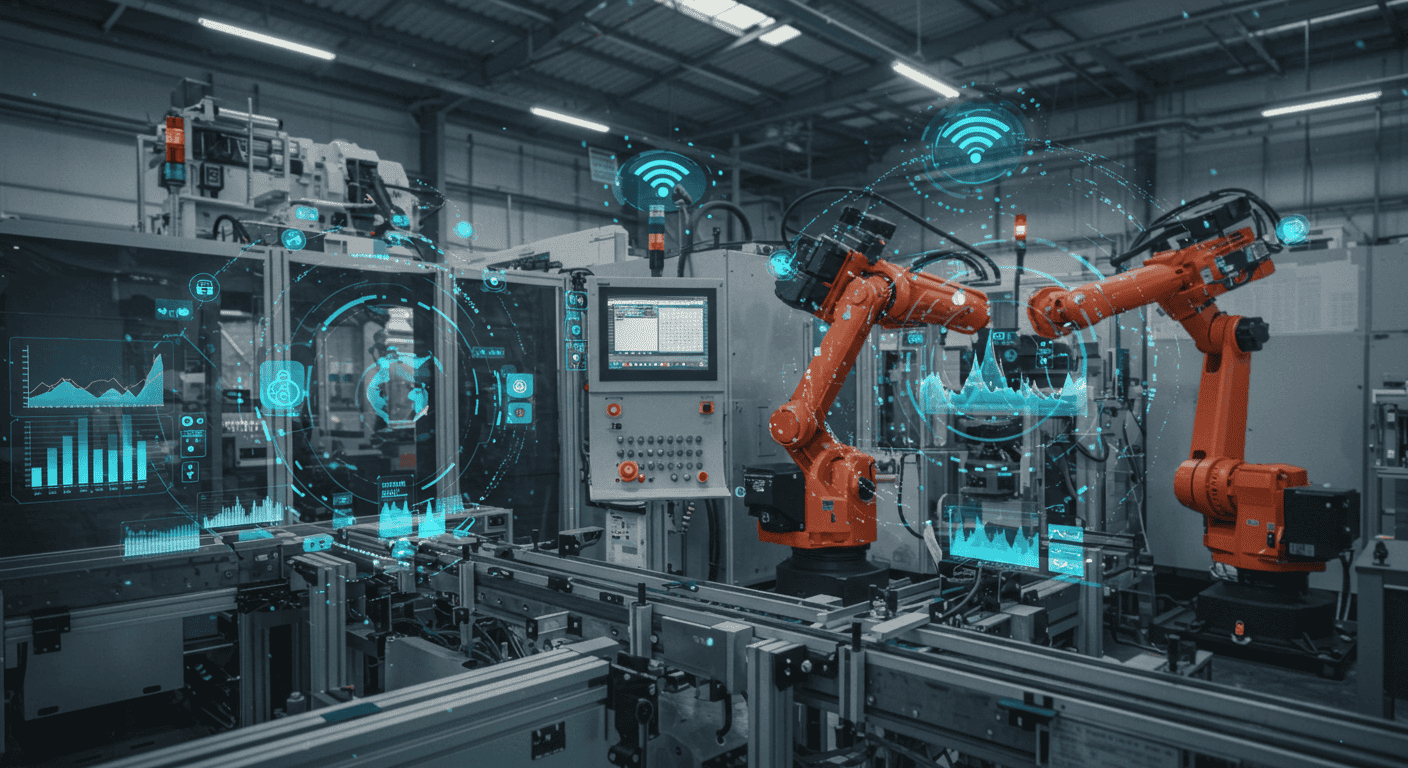

In an era defined by rapid technological advances, traditional manufacturing methods are giving way to smarter, more efficient processes. At the forefront of this transformation is the concept of the digital twin: a virtual replica of physical assets, systems, or processes that enables real-time monitoring and data-driven insights. With the advent of Digital Twins 2.0, AI-powered simulations are taking this paradigm to a new level, merging artificial intelligence, Internet of Things (IoT) connectivity, and next-generation networks like 5G to unlock unprecedented operational efficiencies.

What Is a Digital Twin?

A digital twin is more than just a 3D model; it’s a dynamic, data-driven representation of a physical entity. By integrating sensor data, machine learning algorithms, and historical records, digital twins provide a holistic view of asset performance, environmental conditions, and process flows. Engineers and managers can interact with these virtual counterparts to conduct what-if analyses, detect anomalies, and predict system behavior under different scenarios.

Evolution to Digital Twins 2.0

While early digital twins focused on static visualization and basic analytics, Digital Twins 2.0 leverage real-time AI-driven simulations and advanced analytics. Key advancements include:

- Self-learning models that adapt to new data streams and improve predictions over time.

- Edge computing integration to process data closer to the source, reducing latency and bandwidth demands.

- High-speed connectivity via 5G and private networks for uninterrupted, secure data flow.

- Cross-domain interoperability enabling digital twins to communicate across supply chains, plants, and partners.

The Role of AI in Next-Gen Digital Twins

Artificial intelligence is the engine powering Digital Twins 2.0. Machine learning algorithms can analyze terabytes of sensor data to uncover hidden patterns, detect equipment drift, and predict failures before they occur. Deep learning networks can simulate complex physical phenomena—such as heat distribution, vibration signatures, or fluid dynamics—far more accurately than rule-based models. This empowers manufacturers to optimize operations, reduce downtime, and extend asset lifecycles.

Integrating IoT and 5G for Real-Time Insights

IoT sensors embedded in machines, conveyor belts, and robotics gather high-frequency data on temperature, pressure, speed, and more. When paired with 5G or private low-latency networks, data is streamed in real time to AI engines and digital twin platforms. This tight integration ensures decisions—like adjusting production parameters or scheduling maintenance—are made with minimal delay, boosting throughput and quality.

Key Benefits of Digital Twins 2.0

Organizations deploying AI-powered digital twins report transformative results across multiple dimensions:

- Predictive Maintenance: Anticipate equipment failures days or weeks in advance, avoiding costly unplanned downtime.

- Operational Optimization: Fine-tune process parameters continuously to maximize yield and energy efficiency.

- Cost Reduction: Lower inventory levels and maintenance spend by shifting from reactive to proactive workflows.

- Design Innovation: Simulate new product variants digitally, reducing prototyping cycles and accelerating time-to-market.

- Collaboration: Enable remote teams and external partners to interact with the same virtual model, improving coordination.

Overcoming Implementation Challenges

Despite their promise, implementing Digital Twins 2.0 can pose challenges. Organizations must address:

- Data Silos: Consolidating data across legacy systems, ERP platforms, and IoT networks requires careful planning and standardization.

- Security and Privacy: Protecting sensitive operational data demands robust encryption, access controls, and network isolation.

- Skills Gap: Hiring or upskilling personnel in AI, data science, and digital engineering is critical for sustained success.

- Scalability: Ensuring AI models and digital twins can scale across thousands of assets without performance bottlenecks.

Best Practices for Successful Deployment

To maximize ROI and minimize risk, manufacturers should follow these guidelines:

- Start Small: Pilots on critical assets help validate ROI and refine data pipelines before enterprise-wide rollout.

- Leverage Modular Architectures: Use microservices and containerization for flexible, upgradeable platforms.

- Ensure Data Quality: Implement governance processes to clean, label, and normalize sensor inputs.

- Foster Cross-Functional Teams: Align IT, OT, and data science experts to bridge domain knowledge gaps.

- Measure and Iterate: Define KPIs such as OEE (Overall Equipment Effectiveness), MTTR (Mean Time to Repair), and energy consumption to track progress.

Future Trends: Beyond Manufacturing

Digital Twins 2.0 will expand beyond the factory floor. Emerging applications include:

- Smart Cities: Twin virtual models of urban infrastructure for traffic management, energy distribution, and disaster response.

- Healthcare: Patient-specific digital twins to simulate treatment outcomes and optimize care pathways.

- Supply Chain Logistics: End-to-end visibility and scenario planning across global transportation networks.

- Energy: Virtual power plants balancing renewable inputs with grid stability in real time.

Conclusion

Digital Twins 2.0 represent a quantum leap for Industry 4.0, fusing AI, IoT, and 5G to deliver real-time, predictive insights at scale. By embracing modular architectures, strong data governance, and cross-disciplinary teams, manufacturers can harness these virtual replicas to drive efficiency, cut costs, and stimulate innovation. As the technology matures, digital twins will permeate every sector—from smart cities to healthcare—heralding a future where physical systems and their virtual counterparts operate in seamless harmony.

Learn more about: AI-Driven Synthetic Data Generation: A Game Changer for Data Privacy and Model Training

Leave a Reply